LASER BISMARK MACHINE

Machine on stand for coupling two or more rows of chains through single or alternate pitch. Single phase power supply, variable speed, manual pump centralised lubrication, control panel for setting the machine function parameters, auto-centering guides adaptable to chain width, electronic chain winder, chain end sensor. Machine is predisposed to be used with soldering laser.

-

Industry 4.0

-

High speed

-

Laser

- Main features

- Ball chains: Coupled in 2 o more raws, in square or tube shapes

- Cable chains: Coupled in 2 o more raws, in square or tube shapes

- Box chains: Coupled in 2 o more raws, in square, tube, rectangular shapes and 45°

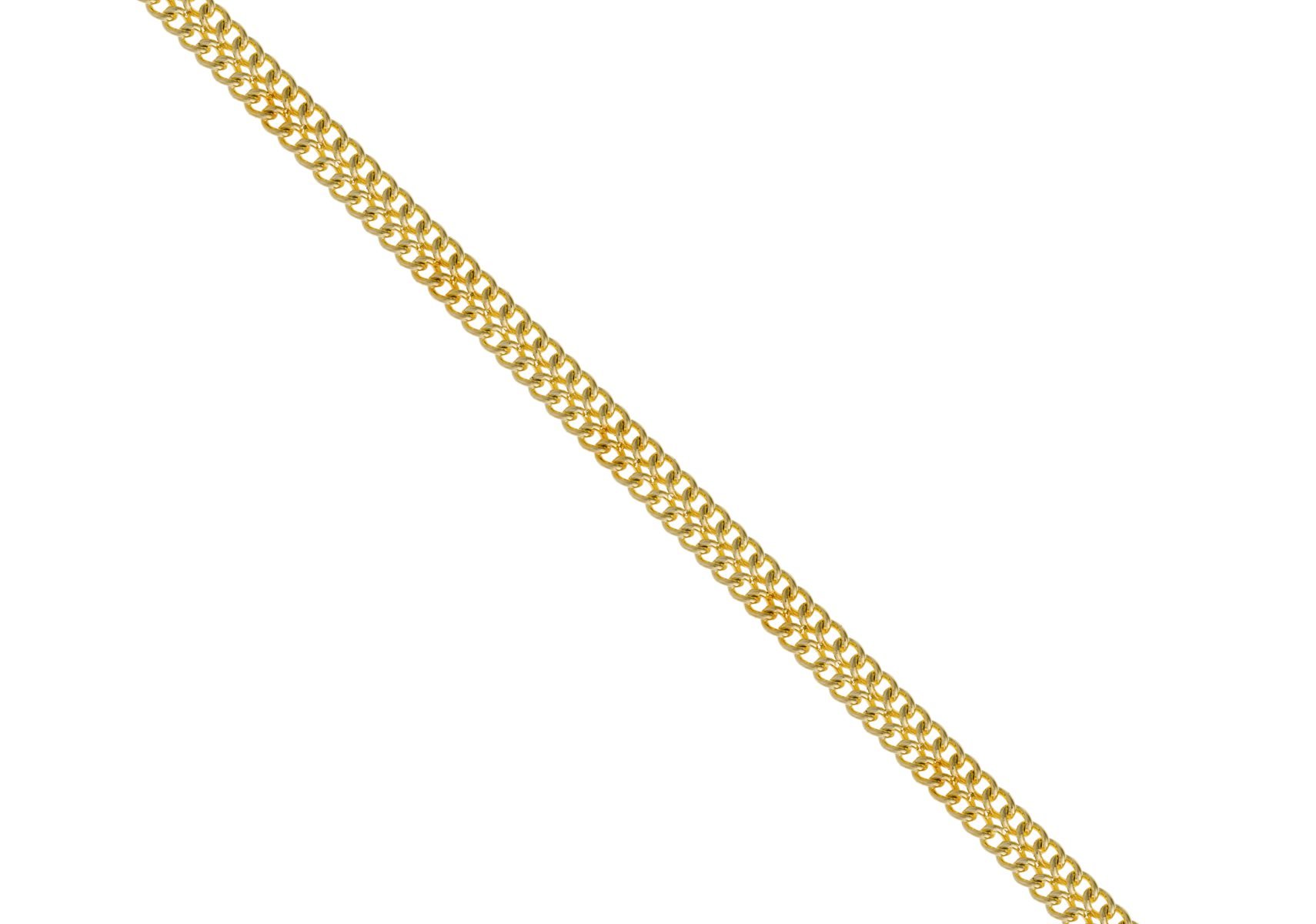

- Curb chains: Coupled in 2 o more raws, arrow, franco, double franco e tube

- Speed: 400 sold./min