BZ

Byzantine

Discover

Discover

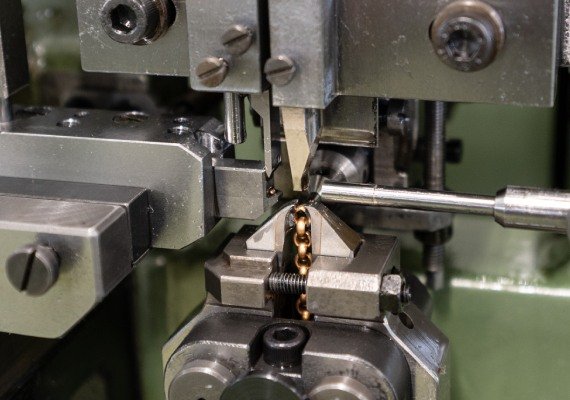

Chain production system entrusted to the formation of the link by feeding the wire in a rectilinear manner onto the facon pin and hammer, and forming the link in the vertical direction “Vertical” chain machines are those whose operating principles are linked to the formation of the chain in a vertical direction. The feeding of the wire takes place laterally with respect to the link formation area, via a system of dowels, according to a “pilger stroke” type advancement, with each stroke, the wire is cut to a length equal to the length of the link by a blade perpendicular to the wire, a pin with the internal shape of the link pushes the length of wire vertically between a pair of facons, also called clamps, which have the external shape of the link, during its vertical descent, the pin pushes and positions the piece of wire between the facons, which, when closed, bend the piece of wire, making it take on the internal shape of the facons, by closing on the wire, the facons form the link, and a hammer descends vertically onto the link’s joint to permanently close the ends of the wire with the desired shape, ensuring contact is made between the two ends, with the newly formed link inside, the facons rotate 90° to offer the space necessary for the insertion of the new piece of wire, then drop the link just made, and begin to form a new link, giving shape to the chain.